"CLOTTING" OF BUSINESS PROCESSES

Clotting of business processes

(FRAGMENT)

(Warning for business-trainers and consultants! The use of this material without the Author’s permission is prohibited)

A fragment from the presentation of Sychev S. "Optimizing business processes" on the TRIZ-RI FORUM "Open business methods and technologies", Moscow, 27th of September 2011.

Two great people have given their opinions about optimization: "The only way to optimize an expensive project – is to close it" (Peter Druker) and "An ideal system is one which does not exist but its functions are being fulfilled" (Genrich Altshuller).

This material is dedicated to (based on TRIZ) the methods of reducing work while keeping and improving its results. In this part of the work, following the steps of the Classics, we formulated the following: "The best work is one which You do not have to do but still get results from it".

A few years back, there was a heated discussion on the popular business-forum www.triz-ri.ru/forum.

Among other interesting things, the following was noted:

- If Vanya made a broom and Masha used it to sweep the floor, then who actually got rid of the dirt from the floor? – Provocatively asked one of the opponents (defending formal logic).

Another opponent, defending innovative and entrepreneurial logic, retorted as such: a smart person will not operate with “brooms” and “dust-bins”, but will think about reducing (in this sense, getting rid of dust) work for cleaning without causing harm to cleanliness.

This opponent answered:

- If Vanya made the broom, then he reduced the work of Masha (if she did not have a broom before that). And this is the only worth of the broom.

- If Vanya made a good broom, then he reduced the work of Masha even more (if she had a worse broom than the one Vanya made before).

- If Vanya developed a method to clean faster and sweeping without much effort apart from inventing the broom, then he did NOT actually reduce DUST, but the work of Masha even more.

The real noble goal of Vanya was not "to make yet another broom", but in such doing, plan a cleaning system so that Masha never again swept the floor herself, and still ensure cleanliness. There is no other clearer ideal for Vanya (as the creator of the cleaning instruments) at his work.

But what does "reducing work" mean? We had "work" and we had "objects".

Both of them can be:

- removed,

- devaluated and made disposable,

- on the contrary, rendered more valuable, if we struggled for that before,

- sent to the super-system,

- force to self-execute.

It is better to begin the optimization with the "objects", and not from the "work". Get rid of the "object" – not all the work linked with this object will be needed. I.e. even if you get rid of one of the objects, You remove "a package of actions".

THE "EXTERMINATION" METHOD

If you wish to simplify any given work, check whether it is possible to work without the object, with which this work is linked. It is not required to clear the board when you have a projector. The speed of processors increase hundred-folds but the amount of energy required to operate it does not increase. Computers get better, but their sizes get smaller, they are already hiding in telephones.

Not so long ago, we used to have cassettes with films to "transfer music and films". Now there are no films, but we still transfer music and films. The interactive screen (touch screen) is used to perform several functions and it got rid of the need for a keyboard and a mouse. Enormous monitors have been replaced by light and flat ones, and afterwards they shall also disappear like self-beings: smart curtains and smart wallpapers will show us everything we wish to see, and developments in 3D technology will perhaps even reduce the use for surfaces.

The law of increasing the level of ideality ("there is no ideal object, but its functions are being fulfilled"), formulated by Genrich Altshuller, is described in details and hundreds of examples, which illustrate it can be found on the following site www.altshuller.ru

Here we shall discuss its application in what can seem to be a simple and rather bureaucratic example.

EXAMPLE

Filling-in the reception of feedstock

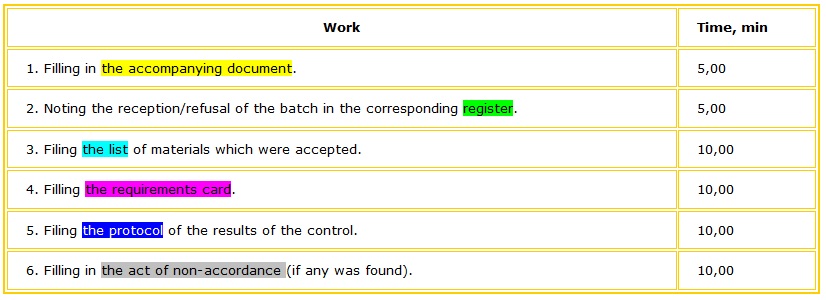

This work consists of the following operations:

Total time for the cycle = 50 minutes (almost 1 hour for 1 portion of received feedstock). Lets’s suppose we have 100 of these operations. We thus get 5000 minutes. Or almost 84 hours. More than 2 weeks.

Hence, in accordance with the ideality principle, we shall try to make the objects of this work unneeded. We have 6 of these (highlighted in different colors here-above), not considering the feedstock itself.

We are talking about the following objects:

- The Accompanying document,

- The register,

- The list of materials which were acceptedd,

- The requirement card,

- The protocol of results of the control,

- The act of non-accordance.

THE FIRST VERSION

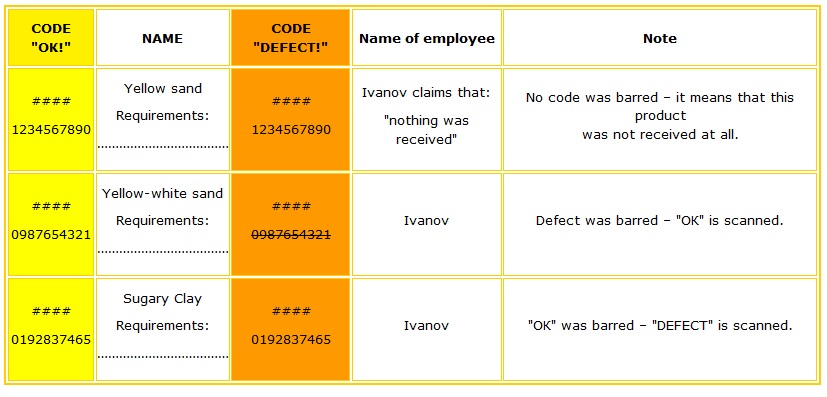

First there was the attempt to develop 1 document instead of 6, consisting of the requirements-card and a universal consignment at the same time. Let us call it "UD" (universal document).

The idea was as follows: The requirements are described for each part of the consignment. Furthermore, each part has a product code, let it be a bar code.

"Universal Document"

On reception:

- We note the received parts (5 minutes), including:

- If everything is "ОК", we bar the code in the field "defect" (i.e. it is "NOT A DEFECT"),

- If it is a defect, we bar the code in the field "ОК" (i.e it is "NOT – ОК"),

- Where anything is barred, the employee leaves his signature (in the next field), for example, "Ivanov",Where it is empty (there is no signature), the computer automatically prints the phrase: "Ivanov claims that: "Nothing was received";

- We pass the "Universal Document" in a scanner (10 seconds):

- Scanning is done;

- There is an automatic processing of different documents (the act of acceptance, the act of defected goods, the application to the accompanying document, etc. – whatever else we wish for). Even better, 1 universal act with reports about the acceptance or refusal in the required number of copies;

- The document (s) is (are) printed;

- The document (s) is (are) signed;

Not more than 5 minutes are required for sections 3, 4, 5 (for the whole process). Or ~ 10 minutes for the whole cycle (instead of 50 minutes). I.e. it was reduced 5 times. For 100 such operations we get 1000 minutes or 17 hours (and not 84 hours).

But we only partly fulfilled the recommendations. We really rendered part of the objects futile. From 6 objects, only 1 is left.

But let’s move on. This 1 object, though single, is still long and not user-friendly enough. Let’s suppose that the enterprise is huge and the “footcloth” is several meters long. Then the operation describe here-above under section 1., could take more than 5 minutes.

Here some might say that we would use the computer immediately etc. but let us see how this operation:

- Should be performed by entering data and without making any error,

- Should be noted in the corresponding way and not make any mistakes.

These two operations should be performed many times – and this is not comfortable as a fact. When someone looks at a large field, he sees the whole sheet immediately. Of course the sheet can be divided into an archive, but then it should be supervised (update, add etc.).

That is why

THE SECOND VERSION

We shall try to increase the ideality level.

- We use an interactive monitor.

- And let each group of items have its own colour.

- Let us try to “visualize the logic of the group of goods”, for example:

- sand

- clay

- stones

- ...

- By clicking on the “colour” twice, we open the group:

- Sand of sort 1

- Sand of sort 2

- Sand of sort 3

- o...

- Etc.

On the interactive monitor:

- We get a drop-down list of the level we need (for example, at the level of our "UD"),

- The employee touches the button "defect" or "ОК",

- The rest is analogous to what is described above (only there is no scanner),

- Furthermore, since the employee entered using his account login, no signature is required.

Let’s calculate:

- Opening the required level (once and for long, let’s suppose, 3 times per shift – since the goods of one type go as a "flow"). That means 20 seconds for the operation or 1 minute per shift.

- The choice of the employee and touching the corresponding button ("ОК" or "DEFECT"). This would be 5 seconds for such a technology. Let us suppose that there were 100 tasks. That would mean 500 seconds. Let’s round up to 9 minutes.

Hence, 9 minutes for 100 operations. And not 84 hours and not even 17 hours.

If you were to describe any process from Your business, then choose all the objects from this description and think: which ones of them you can get rid of.

For supplementary examples, please see hundreds of them on www.altshuller.ru

THE "DEVALUATION" METHOD

If You want to simplify any work, check whether it is possible to devaluate the object, on which this work operates. We do not have to wash a plate if it disposable.

"Disposable tissues have gained such a popularity in Japan nowadays, that using a cotton handkerchief is not only considered as non-fashionable but also non-hygienic" –writes the impressed E. Toffler in 1970 in his book "future shock".

The fact that innovations on objects make them lose their value and in a certain way makes them disposable is already popular knowledge. It is easier to "throw away and exchange", instead of constantly checking and recovering parameters, status and of course reusing.

For example, in the case of the disposable syringe, work (whole bunches of business-processes) about the cleaning and sterilization simply disappeared, but the result is still achieved.

There are disposable tableware, disposable tooth-brushes, disposable umbrellas, disposable lighters, there are even disposable mobile phones and disposable cameras, as well as disposable clothes made from paper of from a different disposable material.

Maybe these examples will seem small to You, even frequent or benign (what is so formidable about a disposable umbrella). After all, there are disposable diapers (bibs, nappies, etc.), disposable towels, disposable plastic bottles for drinks, beer cans (well, they are not reusable, are they?), and packages like "Tetra-Pak", etc.

And (attention please!) what is important is not that these familiar disposable objects pushed out the "long-lasting" ones from the market, which performed the same or similar functions, but actually, that they rendered a whole series of business-processes, which were "attached" to long-lasting objects, useless.

Now let us drop a “more substantial” view on the objects:

- "Hard-disk memory" becomes less and less expensive and do many of us check the volume of our computers´ hard-disks with utilities? (it was done before). No, we already don’t check our flash-disks, we just update it (we simply back-up the data). It is hence easier to recopy…

- Computers, smartphones and other "smart devices" are becoming less expensive and "only live" about 2-3 years maximum at a specific User, but in the year 1993 we bought the IBM-XT-286 computer on credit and on leasing and within a few years, we did an upgrade on it to save on purchasing a new one. These systems are also getting cheaper and to a certain extent, they "also want to become disposable".

- Offset printing is replacing operative printing (an equipment which will not live as long as a printer).

- And doesn´t the same thing happen with cars (if you do not sell it within three years, you might not sell it at all)?

- If you use well-known means for one-time ideas ("Twitter", "Facebook" etc.), then You know that you are using “castrated blogs”, and if you are using a Blog (for example, a "live journal"), then You know that you are using a "castrated site". The main point is that millions of people use these "castrated products", and "correct sites with unique moves, set for "Your specifications” etc." will soon only be used by their authors only. Maybe they make the site well but consumers do not treat it as valuable. If you consider the trend, then you will find that even web-projects "tend to be disposable".

And let’s check out properties.

- What do you think about a disposable house?

No, it is not just rental (though, rental, house for let and other types of "outsourcing" is of the batch). It is well known that there are houses that are produced at factories and that are later assembled within a few days at the site. And never-mind that people debate NOWADAYS about the poor quality (though quality keeps getting better, and these buildings last for a few decades), -that is not what it is all about. When You will be able to buy yourself a good double-deck house for 40 000 dollars, then this whole idea about "my house – my fortress" will become exotic. You will simply buy another one within three years, in the same way as You change your car or your computer nowadays.

When You escribe any process in Your business, choose all the objects in this description and think: which one of these could be made disposable.

For additional information, please see hundreds of examples on www.altshuller.ru

THE METHOD OF "ADDING VALUE TO SOMETHING BAD"

1. Sea waves are used to clean the surface of a pile jetty; surges in voltage are used to charge a capacitor; when there is a crack in the wall, then the way to stop it is not to close it up, but rather to add a supplementary opening at its peak, hypertrophy of cardiac muscles are treated with an artificial infarct (see also: http://medportal.ru/mednovosti/news/2002/07/10/infarkt).

2. According to international legends or, at least according to the notes of Boris Akunin (http://borisakunin.livejournal.com/8870.html), we owe the persistent French slim women fashion to the wife of Napoleon III, the empress Eugenie, who was very slim and used the principle "turn your defect into an effect". Before that it was fashionable for women to be plump, and the word "razdobrela" (put on weight in Russian) (become better, from the word "dobro" (good in russian)) and the word "khudaya" (slim in Russian) (bad, from the word "khudo") speak for themselves.

Whether it is true or not – we’ll let the historians and dietologists decide, but, if You want to simplify or get rid of any correcting work or if You have to get rid of a harmful or excess object, check whether it is, on the contrary, possible to add value to these imperfections. Maybe it could be new décor and not old furniture.

3. In the old days, not all the Users of the site www.triz-ri.com had fast internet and consequently not everyone’s pages loaded quickly. That is why, during the pauses which occurred while the page loaded, we showed quotes. Only during the pauses. They were so popular, that when most Users had fast Internet, they started asking us to "slow" it down or to have a separate section with the quotes.

4. Some production was being marked at one of the factories we know. First, a colored "test marking" was made on the test product with a special font an only then (after making sure that the "test marking" on the test product was OK) the marking itself was fixed to the main product. (Remember when you first installed your colored printer, it might have "asked" you to print a text page with colored strips , which should have corresponded, - that is actually the "test marking").

As a result, it was not only necessary to send the test product as a waste product but also many auxiliary works would add up to that (the production of test products is also – a business process, which holds many operations, as well as supplementary accounting).

We shall try to change the point of view on harmful objects.

The "harmful objects" here were the "bar codes/strips", which were applied as a colored test marking to the waste test product. The general point of view was such that, if we did the manipulation on the main product, it would not be pretty, and hence the main product would have been wasted.

Let the new point of view be the opposite: "These strips are pretty". And we shall highlight this.

We can fit them into a context:

- In a frame;

- In the footer;

- Make it as part of the product sign;

- As a decoration, so that the strips will be inside as part of the decoration;

- Etc.

Result: now we do not need test-samples, we shall mark directly on ready products. Thus doing, we get rid of all the business processes, which are linked to processing the test-sample: preparing them, accounting, applying bar-codes on them, recharging the equipment etc.

5. By the end of the 80s of the last century, the author of these lines worked in a scientific and technical corporation which solved different "inventive problems" for money. Among them, there was a task about how to reduce the number of waste materials when producing polymers by pouring them under pressure (in special press-templates).

The waste material was the technological remnant of the liquid in the funnel (canal). The whole of the remnants in the funnel was considered as waste material, and it was not very clear what to do with these in the future. As a matter of fact, who would want these pieces of material, similar to each other, and "cut-off" from the main product?

Believe it or not but we actually imagined "special forms" for these canals (funnels), for example, long figures resembling those used to play "pseudo-Arabian games", which (together with the corresponding legends) we invented ourselves, thus turning a waste material into a product.

6. When making metallic and plastic windows, there is a "correctional task" – cutting off the splits remaining after welding two profiles to each other. Not only is this operation a "correctional" one, but t is also “long” and thus gives rise to "bottle-necks" (queues are formed by the corresponding stand and the next operations stall).

If we could avoid cutting these splits. It is not harmful in anyway – it does not disturb anything. And it is in fact, practically invisible, if you do not stare intentionally (who actually intentionally stares at the edge of the window...). Oh, no. "They say it is not good, – when splits are at the corner. It is not esthetic".

The first idea of course was to launch an advanced window intentionally covered with various splits. But it was obvious that there would not be a large audience for the advanced windows.

And what if you pay attention to the production segment? On those corporate Clients who order the windows, for example, for workshops, warehouses, laboratories etc., where the small split at the corner will not bother anybody, and discounts on the prices (for orders which in general, is much more than the average private order) have their weight.

Such a solution cut the roller for extremely big quantities of details and optimize production.

7. Bottles are collected and they are given away for money. If they were also paid for the rubbish which fall in their way they would not fail to pick it up. And if they were given packets of different colors to sort the waste by type, you would thus obtain cleaning and sorting.

So, if You are struggling against bad processes, see whether it would be possible to give value to the bad process instead of fighting it. Let the homeless sort out the waste.

See further examples on www.altshuller.ru

THE METHOD OF "HANDING OVER TO A SUPER-SYSTEM"

There are supermarkets where we not only can choose articles ourselves, but also, in many cases weigh them ourselves, get receipts for the cashier ourselves. There are restaurants where the Clients prepare their food themselves. And there are shops in the format of DIY, where the Clients buy components themselves to assemble "whatever" at home. But let’s get away from shops and restaurants.

EXAMPLE

If you produce many things and, consequently, buy much from suppliers of raw materials and components etc., then glance at the first operation of your technical process. It is not excluded that many of them can be “delegated” to the supplier.

One of our Clients bought many aluminum profiles for the needs of his enterprise. He paid attention on the fact that the first operation "cutting the profile into the dimensions he required" could be easily delegated to the supplier. Before that, the supplier would sell profiles of standard equal dimensions. Consequently, the Client did not only have to cut the profiles into the needed dimensions and processing the corners, but the Client also had waste material for which he simply overpaid, furthermore, a rather costly operation was formed about listing the waste material, storing it, and getting rid of it.

That is why, the Client grouped all his orders by types and proposed the supplier who did not want to lose a large and permanent Client, to supply the profile in groups of the corresponding dimensions. In such a way, he simply got rid of the first technological operations, stopped buying “waste material” and also, got rid of all the business processes, linked with these waste materials.

EXAMPLE

Another of our Clients organized a business "selling supplies" (in the jargon, this is what we call the sales of articles needed by other companies for their own use and not for resale and not for technological aims). That is, it is a large (wide) enough range of items: from spare parts - to stationery.

He organized a large shop-warehouse, where sales were made using the cash-n-carry principle – hence, the Clients would be able to take the items themselves and pay for them at the cashier (like in a self-service shop) or ask to get an invoice for the items they chose and Take them after making the payment and/or ordering a delivery.

Compared to other self-service shops, where the Clients place their goods on a carriage, in this case, it was difficult to use a carriage. First, because most of the items were very heavy and/or large; second, due to the same reasons, only samples were found on the shelves, and unloading was done somewhere else; third, a huge part of the Clients preferred to make cashless payments and a comfortable way for them to convey their choice needed to be organized (a choice which could be very wide).

That is why, next to each sample, there were stickers with the names and bar-codes of each item, as well as the units of measurement (kg, units, sq. meters, кв.метры, running meters) – in such a way that the Client could simply take the sticker and answer to the question "how much" on it (in the box next to the units of measurement). In such a way, the Client simply collected the stickers of those items which he chose, and wrote the amount he needed on them.

Then the Client walked to the cashier and handed over the stickers. The cashier scanned the bar-codes of each sticker as many times as it is specified by the Client, then (if the Client paid in cash) he passed the receipt (the order appears in the warehouse program) or (if the Client asked for a bill) a bill was produced and printed for the Client.

The Client who paid in cash, would receive an order number, would go to the warehouse where he would see a rotating belt (like at the airport), on which the orders were presented, he would collect the goods from the belt himself and would fill in the invoice.

EXAMPLE

You are worried that your cashier might cheat the Clients. And You are thinking of how to check on him:

- Maybe eliminate cash dealings?

- Maybe implement abonnement pay for permanent Clients?

- Maybe the Clients will control the cashier themselves? We shall hang a banner: "if there is an error during the calculation, your whole Lunch will be paid by the company" ... No, not like that. We hang a large smiley :) with a funny note: "You did not get a receipt – PRESS and get a PRIZE!"

- We shall also install a camera (one benefit is that they are getting cheaper) and the video image should be broadcasted on a large screen at the cash point (on a monitor). The cashier will be shown to all the present Clients.

EXAMPLE

You are worried about how Your employees use the Internet? Of course, Your system administrator blocks all “bad IP addresses” , but as a matter of fact You cannot "block all of them". And the "monitoring" itself is quite costly: you need to at least select a list of IP addresses, you should set a list of "white" and "black" IP, You need to formalize an algorithm to find out "strange" traffic and pay for all these activities of the qualified employee (instead of using it for more deserving purposes or economize).

- You simply set a cheap monitor (you might as well use a monochrome screen) in a crowded place at the office. And simply translate the content of the monitors of Your employees in a random order, indicating whose computer is being shown.

EXAMPLE

Many have seen, how during the European football cup 2008, replays of the referee’s controversial decisions were translated from different angles on enormous monitors. Actually, it is not only about the fact that tens of thousands of people see that, but mostly about what the referee feels when he understands that tens of thousands of people are seeing his actions/decisions live, being "here and now".

EXAMPLE

Once, for a friendly cooking session at a supermarket, we were presented a constant broadcast of the degustation in the room where the chefs were working (preparing the muffins). Just imagine, what they felt when the Clients said openly that these muffins were not tasty.

EXAMPLE

Imagine that what is happening in the corridor of administrative offices, where officials receive citizens, is constantly broadcasted on screen. The same broadcast (which cannot be switched off) is transferred to the offices of the higher supervisors and on large screens, which are found in the streets of the town (indicating for example "the FMS, which official, the corridor close to which office…" or "Tax inspectorate of the Kirov region, employee…"). Just imagine that the same is broadcasted on the internet on special sites in social networks, and citizens comment them on the site itself. Every morning the officials are read the printout during the planning.

You cannot do this in your country, but You can do that (or something similar) in your company.

We simplify the way the Client can complain. Not all the Clients will write down complaints or call the administrator, but many will perform simple actions, for example,

- They will press on the button marked "unsatisfied";

- They will spin a "black ball" while exiting;

- They will simply walk out through the gate marked “satisfied” or through the one marked “unsatisfied”;

- ...

It is hard to notice that such a method, not only reduces (sometimes even eliminates completely) operative expenses on control, but also eliminates the problem of "how to control a controller" – this problem is solved completely, since you can strike a deal "within a system" but you cannot do so with a super-system. That is why, this method is known as "handing control over to a super system".

However let’s consider an example.

EXAMPLE

You find yourself at a factory which has a park for service and technological transports which are not only meant for travelling around town (or between towns etc.) but also within the factory territory. The inside territory there is big and many transports are used to carry people as well as to move different cargo. Traditionally, all the problems occurring at the junction “man + fuel depot” (theft, administrative fuel expenses, frequent revisions, staff turnover, which does not lead to changeable employees, consequently to excess staff) are very acute. Just imagine that these are your problems and you have to solve them, What will you do?

Remember: You should not think as such: "How can we simplify/improve the work of the corresponding sections, for example, fuel warehouses?", You should think otherwise: "Why do we need these warehouses?", "When can we do without warehouses at this location?" And, please, do the same as we did in the previous example about the cashier and not only.

We have "resources" – a flow of vehicles, which passes through the gates of the enterprise every day. Who needs this flow? For example, we can propose adequate fuel-station owners to refuel at the entrance (that is, at the entrance gates of the enterprise), and consequently, not only throw the fuel and fuel warehouses into the super-system, but also into the past + get a discount (special price) on the fuel (per volume) + get a structured report on the fuel expenses. This is not only a way to save on fuel expenses, but also eliminate the fuel warehouses from the enterprise and the constant head-ache related to their safety, report (they might be stolen), related to excess staff etc.

And we could try to "improve the administrative system", but that would have been a very expensive error. As you can see, "clouds" are not found only on the Internet.

Hence, if You want to simplify any work, check whether it is possible to “hand object it is related to over to the super-system” or “hand over the work itself to the super-system”. You can sell a lego without arranging pieces. You can sell minced meat without making beef-steaks. And the “cloud” is not found only on the Internet.

See also hundreds of supplementary examples on www.altshuller.ru, also read here: www.triz-ri.com/eng/?id=9981

METHOD "CLOSE WITH OTHERS"

If you wish to simplify any work, check whether any other object, contains an analogous work. It is not necessary to cut down the tree on your own. It will definitely disturb somebody from building a swimming-pool.

The Hong-Kong cards "Octopus", which were initially meant to pay for metro fare, are now being used to pay for almost everything. Advanced restaurants distribute their salads, semi-finished goods, company sauces etc.to supermarkets and sophisticated cafes sell their company ready-made cakes in retail-shops. Most probably, You can continue this list of examples yourself.

No matter what we do, usually, some-where not far away, there is already an external functional resource, which can be used. There are always objects where actions similar to the ones we optimize are already being performed.

Let’s take for example the "Knowledge-force" (№ 7, 1986) journal, told the story of a French radio station, which promised not only information and entertainment to its listeners, but also protection against mosquito bites. Since using the frequency at which it broadcasts, inaudible sounds to the human ear but with detrimental effect on female mosquitoes can be transferred.

Truth or tales, - thought I, while passing by a shop and watching how banking agents propose Clients, who have already bought an item they liked for cash, to purchase the same item but for more expensive, - and on credit. One of these items was a watch which could be winded-up by shaking the hand.

EXAMPLE

By standardizing one of the factories, we noticed how, many people (including skilled employees) bring "something or another" (documents, material samples, samples of raw materials, documents again, etc.) to each other and thus, unproductively waste time.

The solution was to place intermediate (buffer) "stores/mails" at the "crossroads", for example near the mess and/or the entrance, so that employees of the corresponding sections received/sent "everything they desire" to each other while on their way to the mess (or on their way home, but until the entrance). The transfer would be made there. And, obviously, if one responsible person would collect not only his "mail" but also that of the members of his department, then 90% of the lazy excuses like "I was transferring documents" ("I was handing over samples" etc.) would have to disappear.

EXAMPLE

In this story: www.triz-ri.ru/forum/mess.asp?thr=24554#m76088 it is also shown how to receive several results for the same actions.

If You described some processes of Your business and in the same way limited them without affecting the results, then check the rest of the work and wonder whether there are no similar ones among them and gather them into the same groups.

You can avoid waking up early to jog. You can jog to work.

See hundreds of supplementary examples on www.altshuller.ru

THE “COMPEL TO SELF-EXECUTE” METHOD

In 1955, Robert Sheckley wrote the novel "The necessary thing".

Space journeys are very long. Even a science-fiction novelist finds it hard to imagine how many things we should take with us. That is why they only take one thing: A 3D printer (sorry, a "configurator"), which produces any required item... What if it breaks down? Furthermore, Sheckley describes a situation where the required item can only be produced once (it just bugged...). The hero of the novel found a solution: he gives the configurator the task to reproduce itself.

55 years after this novel was published we meet the "RepRap" project = a 3D-printer, which not only can print different objects but also itself: http://vimeo.com/5202148

If you wish to simplify any task, check whether the object with this worked is performed, can do it itself. It is not necessary to follow the girl if she already blushes. Not only girls blush (redden): thermal paint changes colours depending on temperature, strings change their sound depending on the tension on them, and employees and Clients either give or do not give us good news or swear at us depending on the wages and on the efficiency of our business.

EXAMPLE

A thin but strong polymer thread was produced in a small enterprise. At a certain point during production, the ready thread was pulled and then wound around a special cartridge. The thread was long. How should we have controlled its thickness during production if that were to be necessary? Furthermore we should be confident that the material going into the thread "is the one needed", and has not been "mixed" (unfortunately, at other fabrics, even polymers are "mixed").

According to the TRIZ rules, this information should be obtained free of charge… from the thread itself. It is not difficult to guess the solution: it is necessary to control the sound of the tight thread. "A correct" (material, thickness) thread will sound at the standard note.

EXAMPLE

In normal trading houses, there are unreducible item balances. For a large range of goods and when they have a quick turnover (food, for example, and not only), then the corresponding managers or merchandisers should not miss reorder and furthermore, they should not miss to check the suppliers (there are many of them at the same time). Since the information about factual sales and about the corresponding factual remaining balance in a well-organized company are considered in the company database, the unreducible balances are also defined, then it is not difficult to make a service which, at the right moment will send an e-mail to the suppliers and/or an sms reminder by itself: "Product N is nearly over. Make us the best proposal right now". In such a way, we get rid of human work which is linked to monitor remaining goods of numerous items and the administration of the order function is simplified.

Most probably, the Reader himself can give several examples relating to "automation". SMS and/or internet notifications about any event, the reaction of the indicator of any measuring system etc.

However, try to automate only those processes which could not be "clotted". And let the automation eliminate some work. It is erroneous to automate work and their "business processes" without limiting them.

If You described any process in Your business, then choose all the objects in that description and think: could each one of them self-perform its work. Or at least send a signal. It is not necessary to follow the girl if she already blushes.

See hundreds of supplementary examples on www.altshuller.ru

This material is also published on the site "Open advertising and PR methods "Advertising dimension" December 6th 2011